Welcome to Wassermann Hamburg

Quality made in Hamburg · GERMANY

Wassermann is a medium-sized, owner-operated company with head office in Hamburg. We design and produce high-quality technical devices in Germany. Our main users are dental laboratories, dental clinics and various industrial areas worldwide.

The first foundation stone for Wassermann Dental-Maschinen was laid in 1927, when Hamburg entrepreneur C.H. Wilhelm Wassermann began to repair dental equipment and tools as Feinwerk Hamburg.

Thank to our flexibility, up-to-date technology and first-class quality standards also other industries have profited from our success for many years. We don't just keep our knowledge to ourselves – we share it around.

Nowadays FEINWERK HAMBURG is a competence centre for the development and production of own and other products. Since Decades, we are a reliable partner of renowned companies worldwide. Whether for sheet metal processing, turning, milling or the assembly of small and medium series, we can support you.

Why a Wassermann product?

Wassermann products are manufactured from high-quality materials and the proportion of plastics used is intentionally kept as low as possible. Our devices are known for their suitability for daily use, functionality and longevity. As a result, the users place high levels of trust in the Wassermann brand. We feel it is our duty to support our customers on a daily basis when it comes to safety, service and productivity. Technological perfection, optimum quality and especially sustainability are the benchmarks we set.

Thanks to the combination of these values, the family-owned company, since its establishment in 1927, has gained worldwide recognition as a manufacturer of high-quality products.

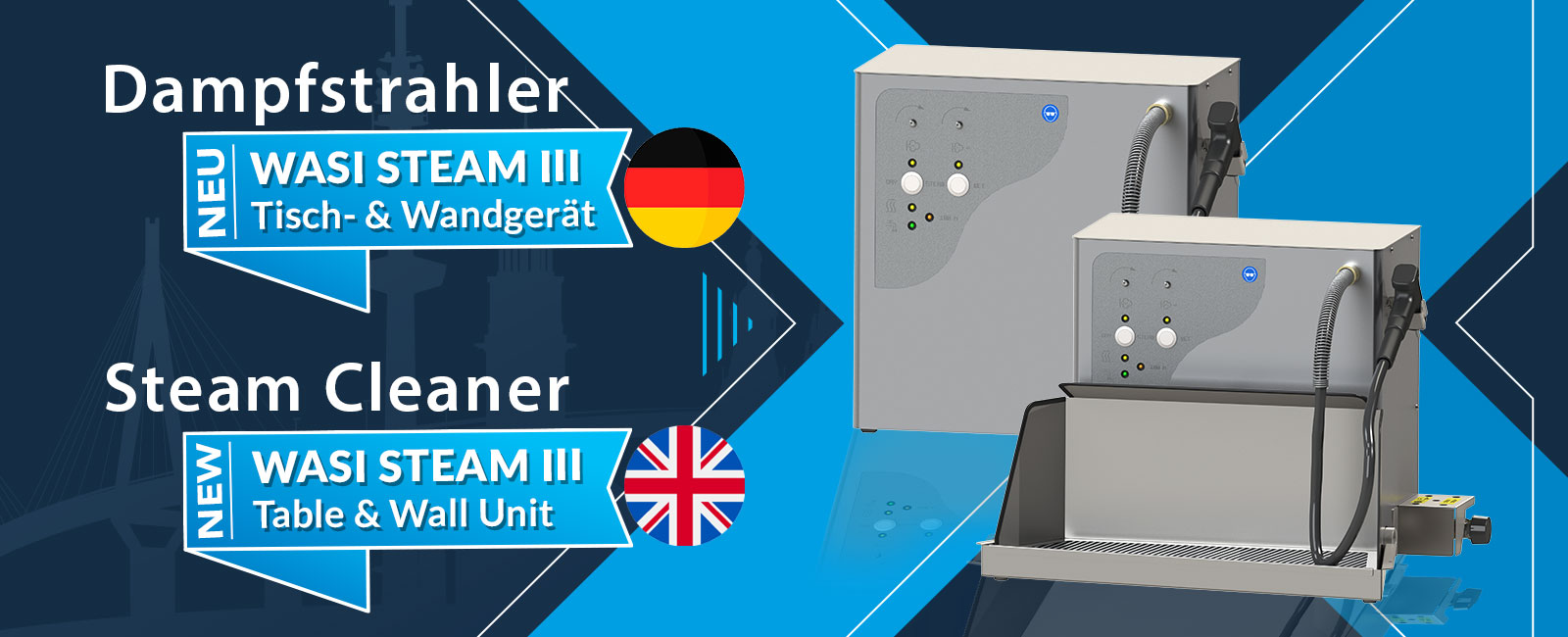

News

The contact form is temporarily offline!

Let´s stay in contact

UPCOMING EVENTS

Click here for NEW DATES and more information.

WE ARE AVAILABLE

Visit us and check our QUALITY MADE IN GERMANY online and if you have any questions please don't hesitate to contact us.

Stay healthy.

Your WASSERMANN Team

Price List

Prices available by request

For further information please write to export@wassermann-dental.com

Thank you.